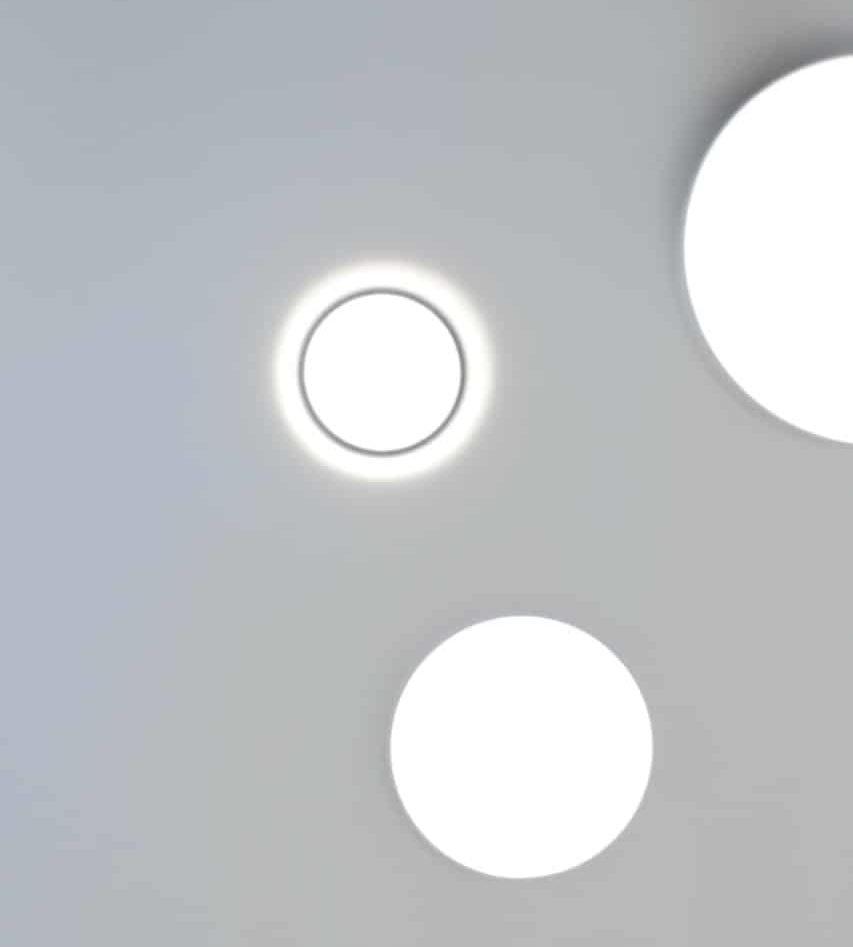

Circular lighting in a circular economy

The construction industry plays an important role in a circular economy, which also includes circular lighting. Circularity is not a complicated principle. It comes down to minimizing your impact on the environment by keeping raw materials in the cycle for as long as possible. Unfortunately, the implementation of this principle is not as simple. Multiline has been researching the possibilities and benefits of circular luminaires for several years now. We highlight all our findings in this blog post.

Design and production of circular lighting

The first step towards circular lighting begins with the production process. The choice of raw materials, components, assembly and attention to efficiency plays a crucial role. Materials must be chosen carefully and waste must be avoided as much as possible.

Multiline uses extrusion profiles that consist of 70% recycled aluminium. The aluminium profiles can even be disassembled after their period of use. This makes it possible to reuse the basic components (profile, LED board, driver and diffuser). As a result, waste is reduced to a minimum. Therefore, the choice of components and raw materials plays the most important role in the lifespan of the luminaires. If the lifetime of the luminaires becomes longer, the need for new raw materials decreases. In turn, efficiency means that the better the luminaires perform, the fewer are needed to achieve the same results.

Zhaga

The Zhaga standard is an internationally standardized specification of lighting components that can contribute greatly to circularity. Thanks to the Zhaga standard, components can be replaced in case of failure, independent of the manufacturer. Its purpose is to increase the probability of repair, thereby increasing the lifetime of the other components.

Retrofitting existing luminaires

Next to the manufacturing process, the degree of circularity also depends on decisions made when the luminaire has reached the end of its lifespan. You have the option to retrofit older luminaires that require replacement or that consume more energy than needed. For such older luminaires, Multiline often develops a new customized interior. This way, the luminaire can be kept and no drastic technical modifications have to be made to the building, but energy performance will still be improved. By replacing the internal components and light sources you can cut the energy cost in half.

Circularity at Multiline

For our own Multiline luminaires, we can customize them according to the needs of the customer. The installation of LED luminaires doesn’t have to be expensive, as it is possible to modify only the internal components and keep the housing. As a matter of fact, Multiline always opts for high-quality materials, which have a hugely beneficial effect on the lifespan of its luminaires.

In addition to manufacturing and retrofitting, Multiline also pays attention to circularity in its overall operations. For large projects, Multiline delivers products in bulk whenever possible, eliminating the need for separate packaging. For some projects, deliveries can be made in a transport cart that can also be used on site. Multiline also makes agreements with suppliers about packaging that can be reused if necessary. Working together is important to make circular construction possible.

Are you looking for a sustainable solution for the luminaires in your building or company? Multiline gladly offers you advice on customization and retrofitting, as well as a lighting study if desired. Contact us and we will gladly discuss your options.

Looking for inspiration?

Do you have questions? Would you like more information about our products?

Contact usMore news

-

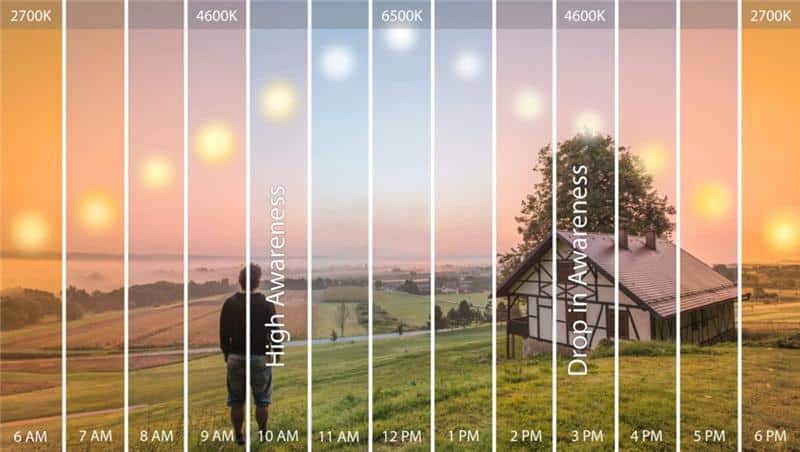

Circadian lighting design: the significance of what you don’t see

For a long time, the visual importance of light was the primary focus. The specific preferences of the user were taken into account: illuminance, color temperature, color rendering or amount of (in)direct light. The discovery of a new light receptor in our visual system in the early 2000s highlighted the importance of the non-visual system of our eye.

Read more -

Lighting trends in 2024

At Multiline, we closely monitor the needs of our customers and partners during the selection process. This makes it easier for us to anticipate new lighting trends. Discover below the trends for 2024.

Read more -

Innovative lighting technology at Multiline

The needs of our clients are constantly evolving. In order to meet this challenge, Multiline is strongly committed to innovation, quality and development. We have a good sense of what is going on in the market by working closely with architects, engineers, designers and installers. These important connections allow us to provide the most innovative lighting technology. In this blog, we explain how we are able to do this.

Read more

blog

blog