New TRUMPF metalworking machine: enhancing customer-focused production

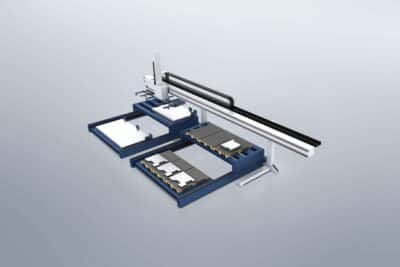

Quality, customization, and reliability are key features of our luminaires. In order to uphold this commitment in the future, we’ve invested in a new metalworking machine: the TRUMPF TruMatic 6000. This takes our production process to the next level, with benefits that go well beyond expectations.

The TRUMPF TruMatic 6000 enables a more efficient, flexible, and even higher-quality production of lighting fixtures, directly benefiting our customers. One thing is certain: the way we handle sheet material has changed forever.

Better products, shorter lead times

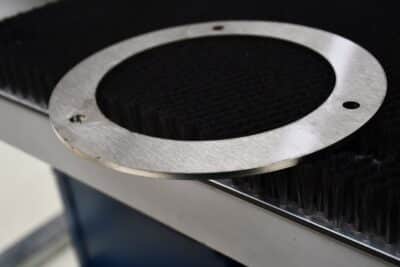

“TRUMPF, a German market leader in laser and punching technology, is highly regarderd in the industry. By combining punching and laser technology, Multiline’s production can integrate more complex shapes and smart features directly into metal parts. This includes processes such as threading, roll forming, or adding reinforcement ribs – all in one automated movement,” explains Francis Sercu. “This results in fewer manual operations, reduced risk of errors, and a finished product that’s quicker to move into assembly.”

Francis Sercu is the product manager at V.A.C. Machines, a family-owned company in Bruges that supplied and installed the machine. For more than 15 years, we have been able to rely on them for our machinery.

Consistent quality, even in small series

“The TruMatic 6000 is linked to the SheetMaster and GripMaster” Francis continues. “This setup allows the machine to automatically load and sort material, enabling Multiline to produce almost hands-off, even for small series. This automation not only guarantees consistent quality but also makes small-scale custom production financially viable.”

For customers, this translates to:

- shorter lead times;

- consistent, high-quality finishes;

- greater design flexibility and custom lighting solutions.

In other words, we are now even better equipped to respond flexibly to the specific needs of our customers – without compromising on the finishing or lead time.

Investing in cutting-edge technology

In addition to installation, V.A.C. Machines also provides training and software support. This ensures that our operators can get the most out of the machine. With the integrated TruTops Boost software, they can switch more quickly between design and production, further enhancing efficiency.

The benefits for customers are clearly noticeable. You receive a high-precision finished product quickly, with integrated features that simplify the assembly process. This investment reinforcers our position as a reliable lighting partner with full in-house production – from design to the final product.

Curious about the possibilities of our custom production?

Are you looking to collaborate with a lighting partner who invests in quality and efficiency, and is ready for the future? Get in touch with us and discover how we can take your project to the next level.

Looking for inspiration?

Do you have questions? Would you like more information about our products?

Contact usMore news

-

Classic rally cars shine bright under Multiline lighting

In April 2025, Squadra – an impressive new experience center - will open its doors to the public. Designed as the ultimate destination for Abarth enthusiasts and classic rally car lovers, Squadra provides a setting where no detail was overlooked. Multiline had the honor of equipping this new building with high-quality lighting solutions, with expert installation by Belcotec.

Read more -

Human-centric office lighting: the impact on our productivity is bigger than expected

A well-designed office is key to employee well-being and productivity. Next to ergonomic furniture and acoustics, lighting also plays a central role. Human-centric office lighting goes beyond traditional lighting solutions. It doesn’t just illuminate a space - it supports the natural biorhythm of your employees. The result? More focus, more energy, and less fatigue during work.

Read more -

Custom architectural lighting: when standard luminaires aren’t enough

Architecture requires harmony, and that’s especially true for lighting. For those seeking seamless integration of light into a design, custom architectural lighting is the answer. At Multiline, we combine aesthetic insights with technical expertise, ensuring that lighting is not only functional but also visually enhancing. In this blog, we’ll show you how our custom lighting solutions blend seamlessly into unique architectural creations.

Read more

blog

blog